The construction industry heavily impacts the environment, producing 3.5 Gt of CO2 annually—equivalent to 1 billion cars—mainly from cement and steel production. To mitigate this, a major shift in building design and construction practices is crucial to cut environmental impact by tenfold.

369 Pattern Buildings

Modular Buildings Platform for Circular Construction

At the time of carrying out this project, Accelerate had a wider goal of supporting public/private partnerships, which later evolved to a more narrow focus on unlocking new markets by overcoming regulatory barriers.

Introduction

Problem

Traditional construction methods rely heavily on synthetic materials and produce significant amounts of greenhouse gases. The construction sector is responsible for approximately 40% of all greenhouse gas emissions and is the largest consumer of raw materials. At the end of buildings’ life cycles, less than one-third of materials are recycled.

The construction sector is one of the least digitized industries in the world, yet both the sector and, on a wider scale, countries face an urgent need for new and more sustainable solutions to comply with relevant EU policies and global targets for reducing greenhouse gases. This concern is especially critical for EU governments, as they have a clear obligation to ensure that all public sector buildings are carbon neutral by 2027.

Solution

The proposed Pattern Buildings solution focuses on creating an open platform for designing and constructing modular buildings, while utilizing biogenic materials such as wood, hemp, and straw.

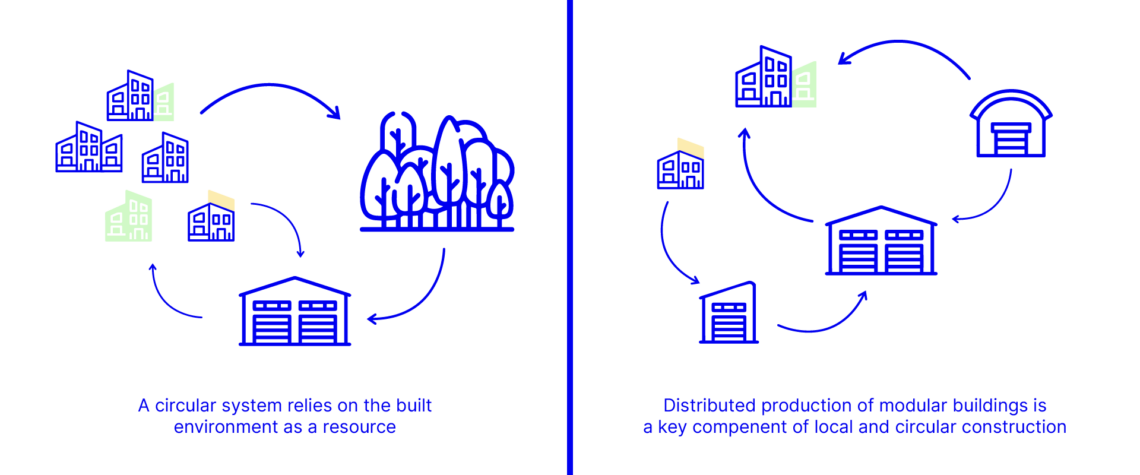

The platform supports the use of standardized, modular components that can be disassembled, reassembled, and repurposed, promoting a circular construction model. By integrating modular design and biogenic materials, the platform aims to drastically cut the environmental footprint of construction and support a transition to regenerative practices.

End Goal

The goal is to advance modular construction practices that significantly reduce CO2 emissions, prioritize sustainable building methods, and promote circular economy principles. With the urgent need for all public buildings to achieve carbon neutrality by 2027, this initiative plays a crucial role in driving low-emission construction, encouraging the use of sustainable materials, and supporting the state in reaching its carbon-neutral objectives.

Outcome

During the Accelerate Estonia project, a prototype of the modular building system was developed and tested for designing kindergartens and office buildings. This prototype was compared with traditional designs, focusing on the use of biogenic materials and their carbon footprint. The comparison showed significant results, indicating that the carbon footprint of modular houses is remarkably smaller—up to three times less.

The project progressed with the creation and construction of a standardized model for large-scale projects, resulting in a new training center for Elektrilevi. Construction moved quickly—from laying the cornerstone to installing the rafters took about a month, with on-site assembly completed in just two weeks. This successful pilot highlighted the practical benefits of modular design, paving the way for broader adoption and further innovation in sustainable construction.

Additionally, in Tallinn, two kindergartens have already been designed using the Mustermaja 369 system, with more planned for 2025.

This innovative building method utilizes modular construction techniques, which consume three times less resources compared to traditional methods, significantly reducing material use and environmental impact.